Send enquiry to Springcoil Ltd. Technical Information

Springcoil Ltd. Technical Information

BRITISH STANDARDS

Unless specific instructions are given tothe contrary, the Company will manufacture components to the tolerances specified in the appropriate British Standard i.e.

Compression springs – BS1726 Part 1 (2002)

Extension springs – BS 1726 Part 2 (2002)

Torsion springs – BS 1726 Part 3 (2002)

Further details available upon request.

MATERIALS USED EXTENSIVELY AT SPRINGCOIL :

HIGH CARBON STEELS :

BS 5216 HS3 / HD3 (unground / ground)

BS 2803 730A65 ND/ HD (Chrome Van unground /ground)

BS 2803 685A55 ND/ HD (Silicon Chr. unground / ground)

BS 1429 735A50 ND – Annealed Chr Vanadium

BS 1429 685A55 ND- Annealed Silicon Chr.

STAINLESS STEELS:

BS 2056 BS EN 10270-3

We are able to supply Type 302 /316/17-7 Stainless springs

HIGH NICKEL ALLOYS:

We stock a wide range of High Nickel alloy materials such as – Inconel X 750, Nimonic 90, Hastelloy C276, Titanium and Phos Bronze.

Out Technical department will be pleased to discuss any aspect of Spring material and advise on which material to use for a particular application.

RATE (LOAD/DEFLECTION)

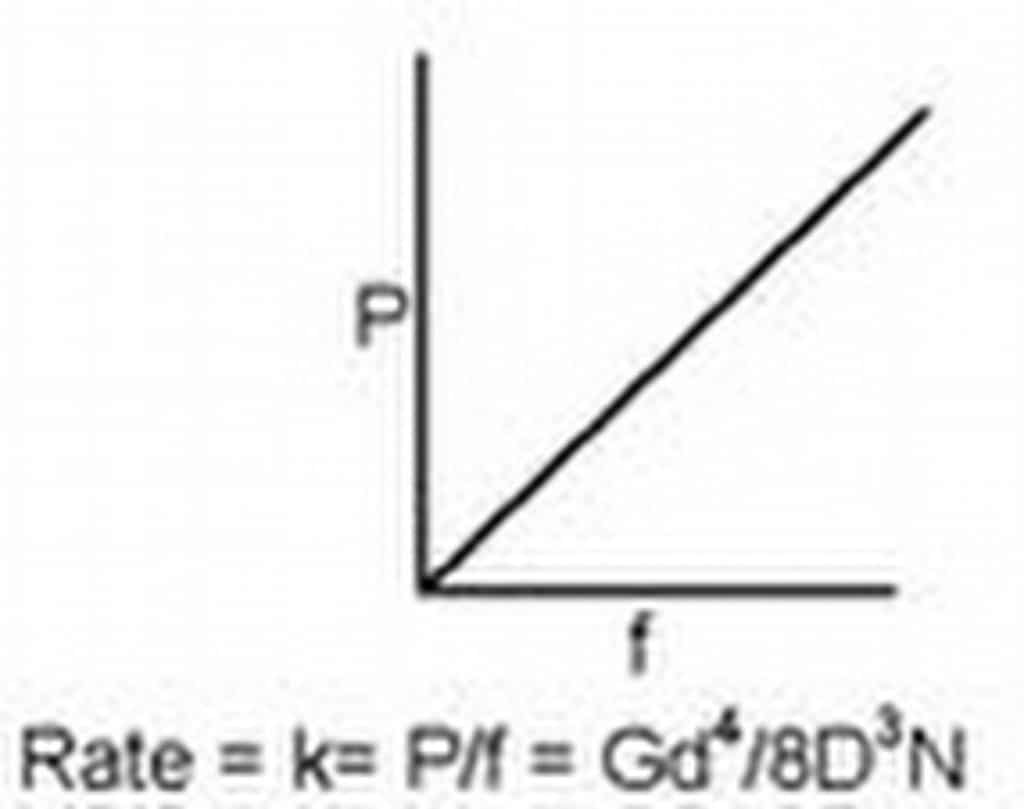

In a helical compression spring design the deflection is proportional to the load. This is the same as most other springs. This means that the load/deflection curve is basically a straight line as you can see in the sketch.

NUMBER OF COILS OR TURNS

Spring rate is inversely proportional to the number of active coils. We suggest that the designer always specify the number of coils as a reference number. This is because, in most instances, the spring manufacturer will have to vary the number of coils to meet the other parameters.

The number of active coils should not be less than two.

In Compression springs the ends of the spring can be closed or open(see diagram on the 'compression spring' page). If closed ends are specified for the design then that means there must be at least two inactive coils. The closed ends can be ground (to provide more bearing surface) or just closed and squared.

There are so many variables involved in spring design and we could fill this page with complicated formulae on loading, stress etc. This may confuse you and lead to incorrect results therefore we strongly recommend that you contact our design department who will be pleased to answer on any technical question you may have.