Send enquiry to Caldo Consultants

Hot Gas Filters

Oil & GasDescription

Caldo hot gas filters are high temperature equipment items for the continuous removal of particulates from air or other hot gases. The equipment consists of ceramic filter elements installed in custom-built vessels fitted with proprietary mechanical parts.

The detail of the design of the filter vessel, the layout and sealing of the filter elements and the integration of the mechanical parts is critical to the achievement of a reliable and cost-effective hot gas filter. Caldo has invested in 20 years of continuous design development based on CAD technology, manufacturing improvements and experience on-site. Caldo is now ideally placed to pass on these designs to our customers, either in the form of complete filtration units, ready to install, or as design technology, to support our supply of filter components.

Ceramic Filter Element

Caldo ceramic filter elements comprise mainly alumino-silicate ceramic fibres. This material has two key properties:

- it is very refractory making it resistant to high temperatures and corrosive gases

- it is a very thin fibre, which is ideal for constructing the low density, high surface area structures that make the best filtration media.

Our ceramic filter element is vacuum formed to the industry standard design; a 1000mm long tube, flanged at one end and closed at the other. It can withstand a temperature of 900 degC and can resist almost all chemical attack.

Element Installation

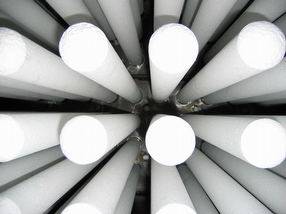

The elements hang vertically from the header plate, which separates the clean and dirty compartments of the filter vessel.

In use the hot gas is sucked through the filter medium from outside to inside, depositing the particles on the outer surface of the medium. The solids form a continuous layer, or cake, on the surface of the element. At controllable intervals a sharp pulse of compressed air or gas is blown back down the inside of the filter element causing a momentary reversal of flow. This reversal causes the accumulated solids to be detached from the outer surface of the filter elements as agglomerates or flakes. The solids fall into the hopper section of the vessel from where they will be discharged. The pictures show filter elements that have just been cleaned – it can be seen that the cake has detached in patches.

Caldo Filter Designs

The design of a ceramic filter is constrained by the need to be able to remove the solids from the elements by reverse pulse cleaning and to be able to discharge the solids from the vessel. Reverse pulse cleaning (see data sheet) requires the elements to be in rows so that the pulse can be applied to more than one element at a time -rows are typically 8 – 20 elements long. Discharge of solids from the vessel requires a hopper section at the bottom tapering to a valve or seal allowing solids to pass intermittently to a removable container.

Hot Gas Filter Capacities

Filters are built in a wide range of sizes for their various duties; typically vessels contain from 48 – 400 elements. In the past, if the duty required more than 400 elements, vessels were installed in parallel to achieve the required capacity. This was undesirable because multiple solids discharge points made the operation more complicated than necessary, and because it was expensive.

Recently Caldo have introduced a new design of vessel to house up to 1500 elements and one of the pictures on the right shows the inside of one of these vessels. This one contains 1,280 elements in 80 rows of 16 elements per row.

Inside the filter vessel, the solids collection screw conveyor can be clearly seen. This draws the solids from the whole length of the vessel to a single discharge point.

Ceramic, Filters, Hot, Processes, gas Product code: Hot Gas Filters

Caldo Consultants

More products from Caldo Consultants

Complete Pollution Control Systems

Hot Gas Filter Components